Images and videos

We would like to present a few images and videos about the everyday life and technological background of EMG-Metall Kft. and our capabilities for better serving our partners and developing long-term cooperation with them. We strove to select images that illustrate the steps of our development, the diversity of our products, and our wealth of laser cutting and sheet punching capabilities, in terms of both our timeline and the range of our sheet metal working abilities.

TECHNOLOGY - LASER CUTTING

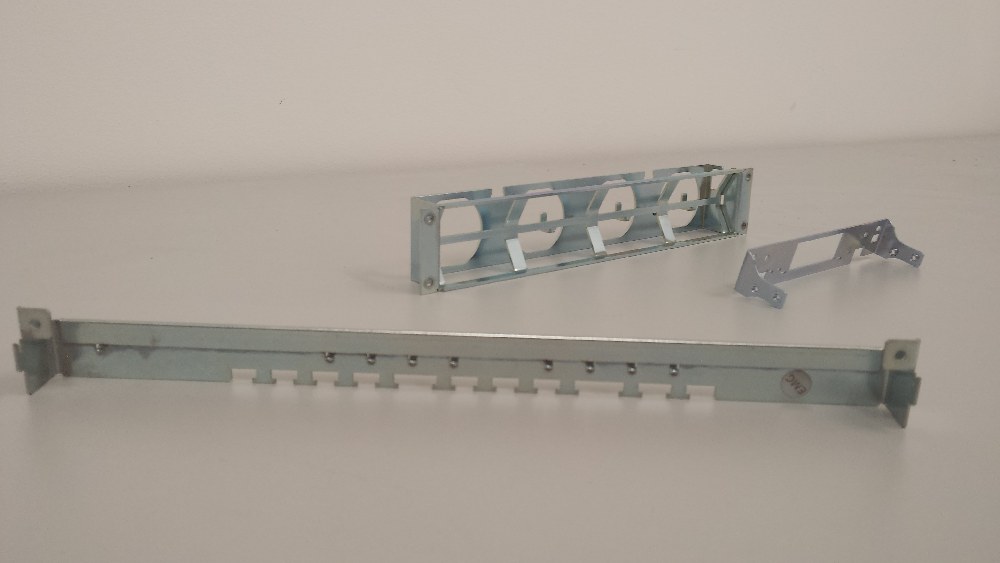

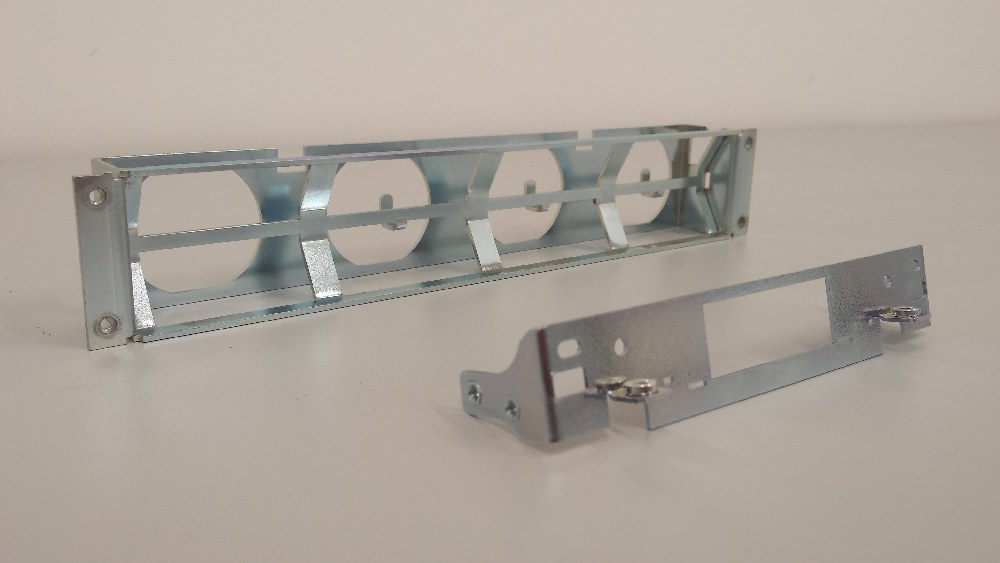

Machining of sheet metal-based products and parts production in small- to medium sized lots using CNC laser cutting machines, machining centres, press brakes, and punching and welding machines.

TECHNOLOGY - PUNCHING

Machining of sheet metal-based products and parts production in small- to medium sized lots using CNC punching machines.

TECHNOLOGY - Powder coating

Pre-treatment with modern duplex technology, using powder paint from a Swiss supplier, with curing in a convection oven.

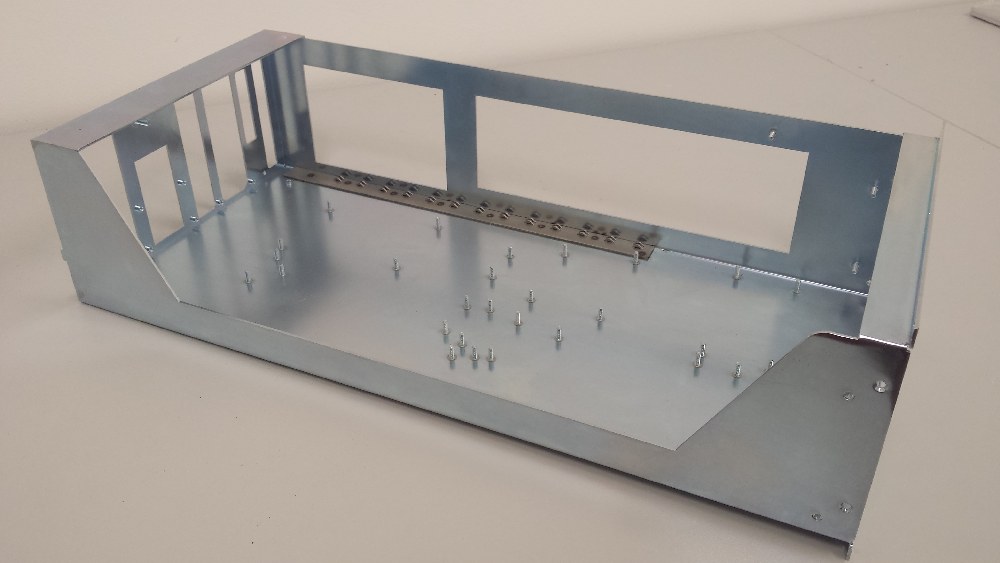

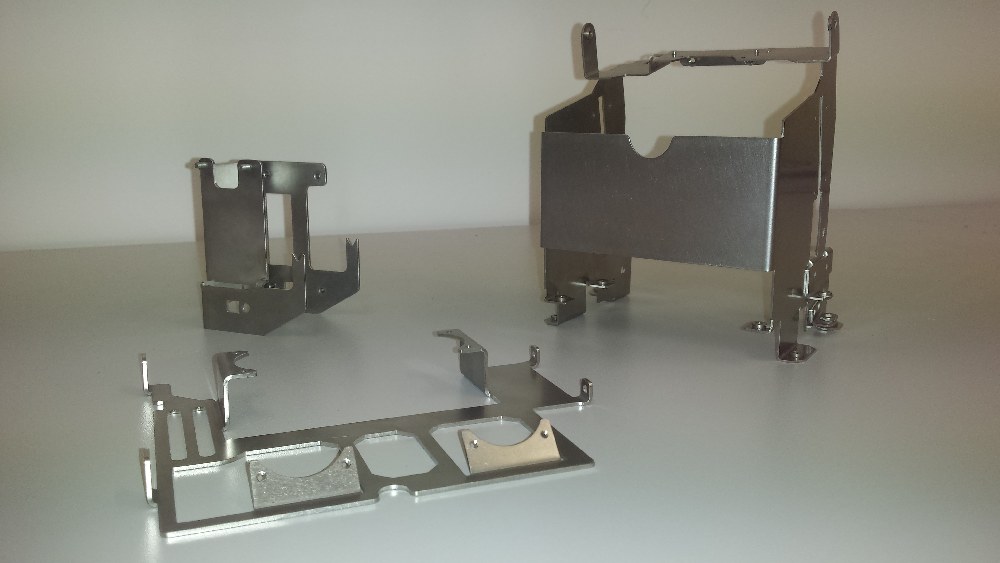

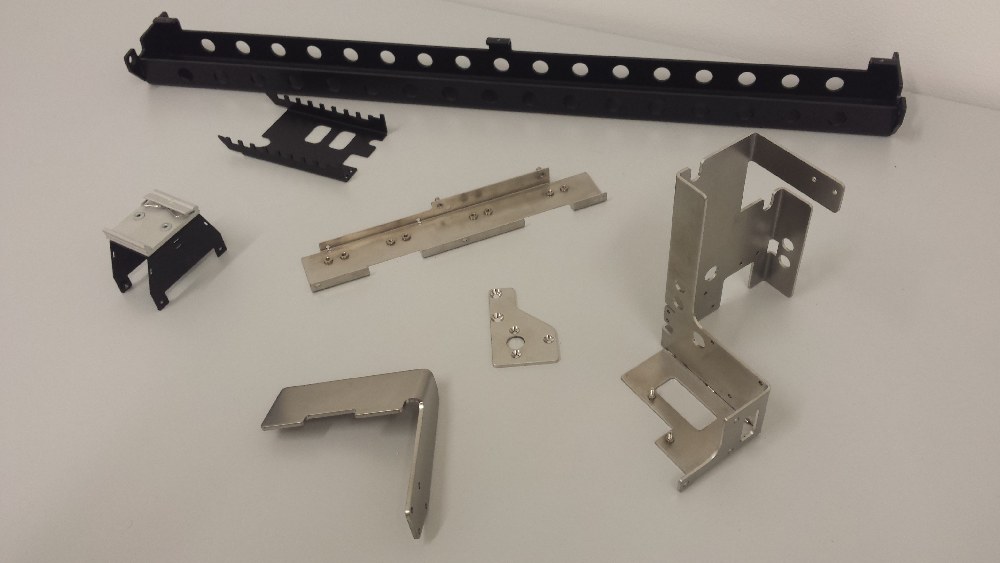

TECHNOLOGY - In-process operations: insertion, welding, bending, drilling

In-process operations on the following machines: Haeger 618 fastener insertion machine, Haeger OT824 automatic fastener insertion machine, Lorch welding machines- (MIG, MAG, WIG), Messer spot weldings, HBS hand and cnc studwelding, Grindingmaster deburring machines, TimeSavers manual deburring machine, sheet metal working machines.

TECHNOLOGY - MILLING

5-axis machining is an effective means to reduce setups and increase accuracy for multi-sided and complex parts.

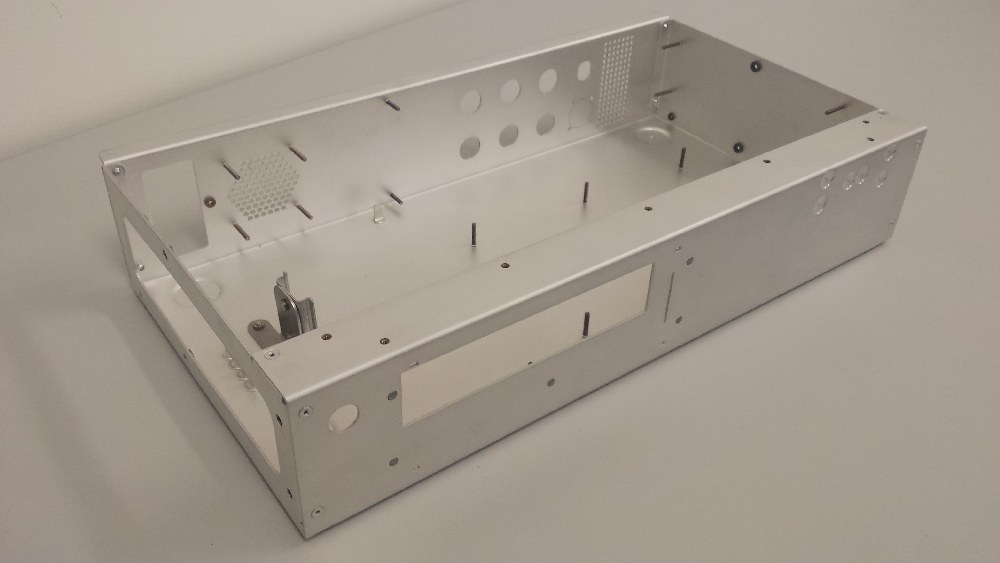

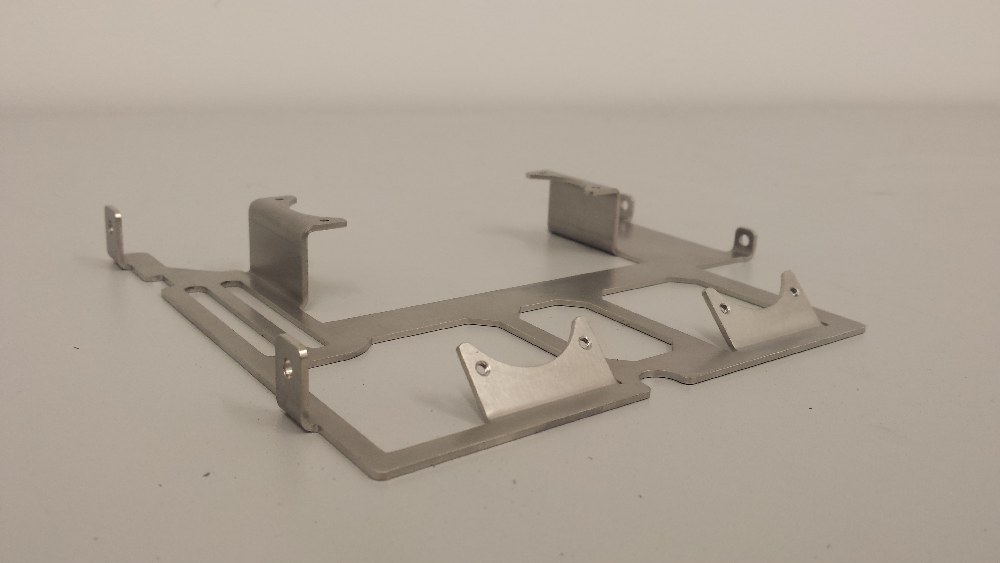

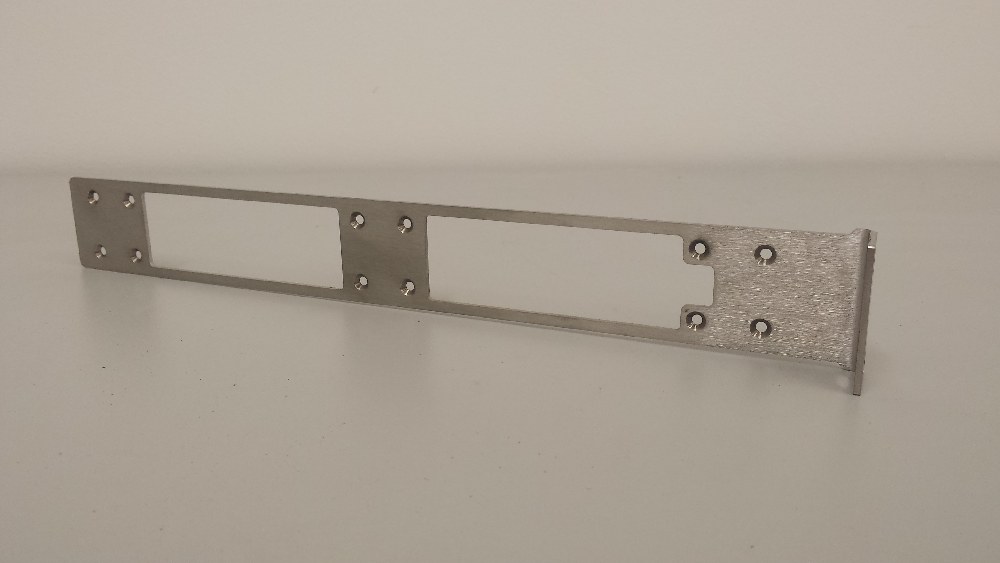

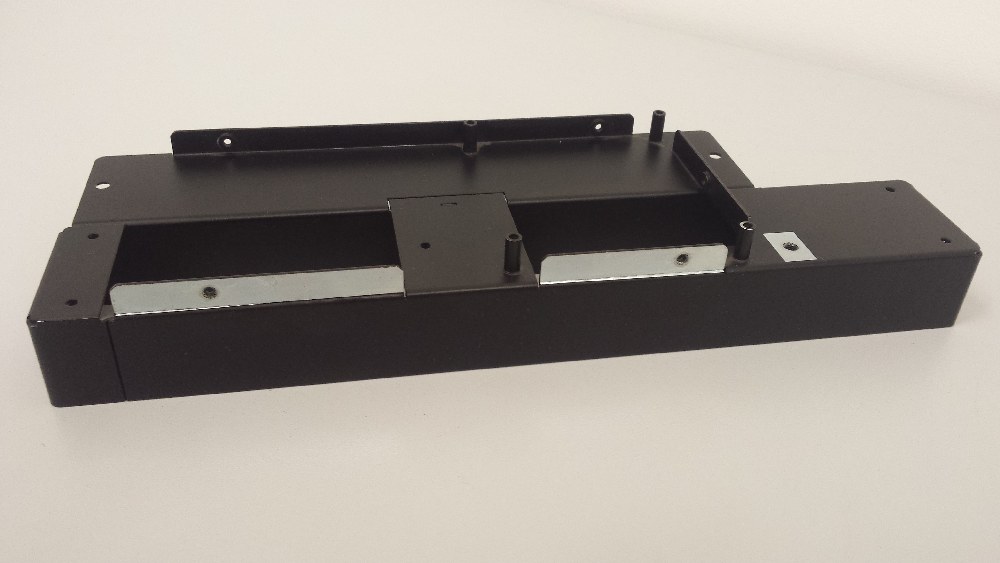

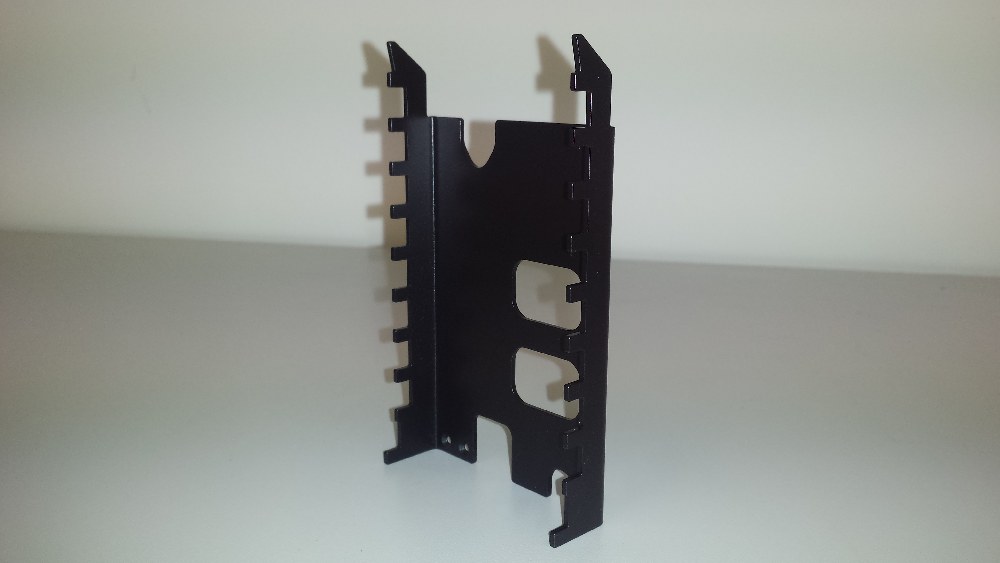

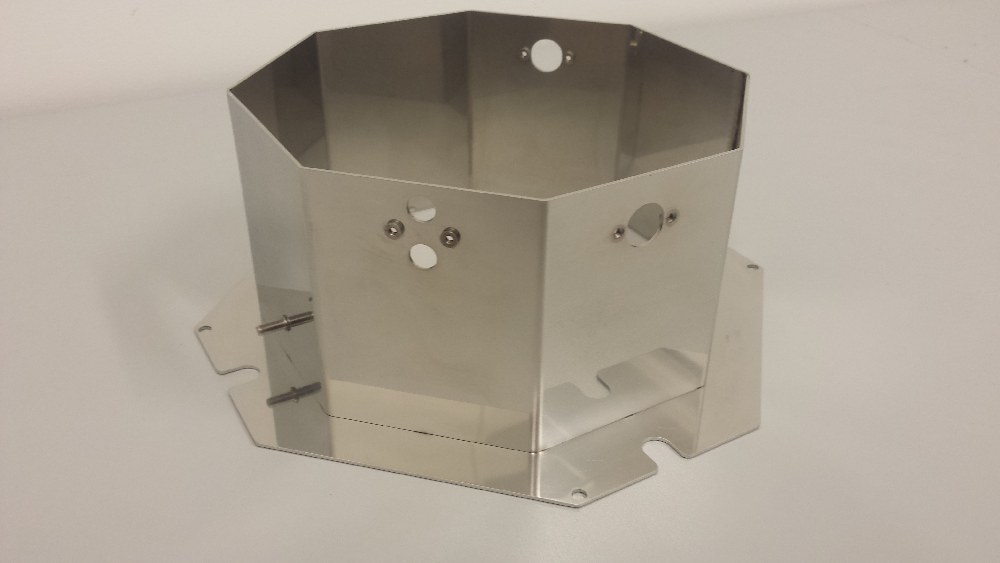

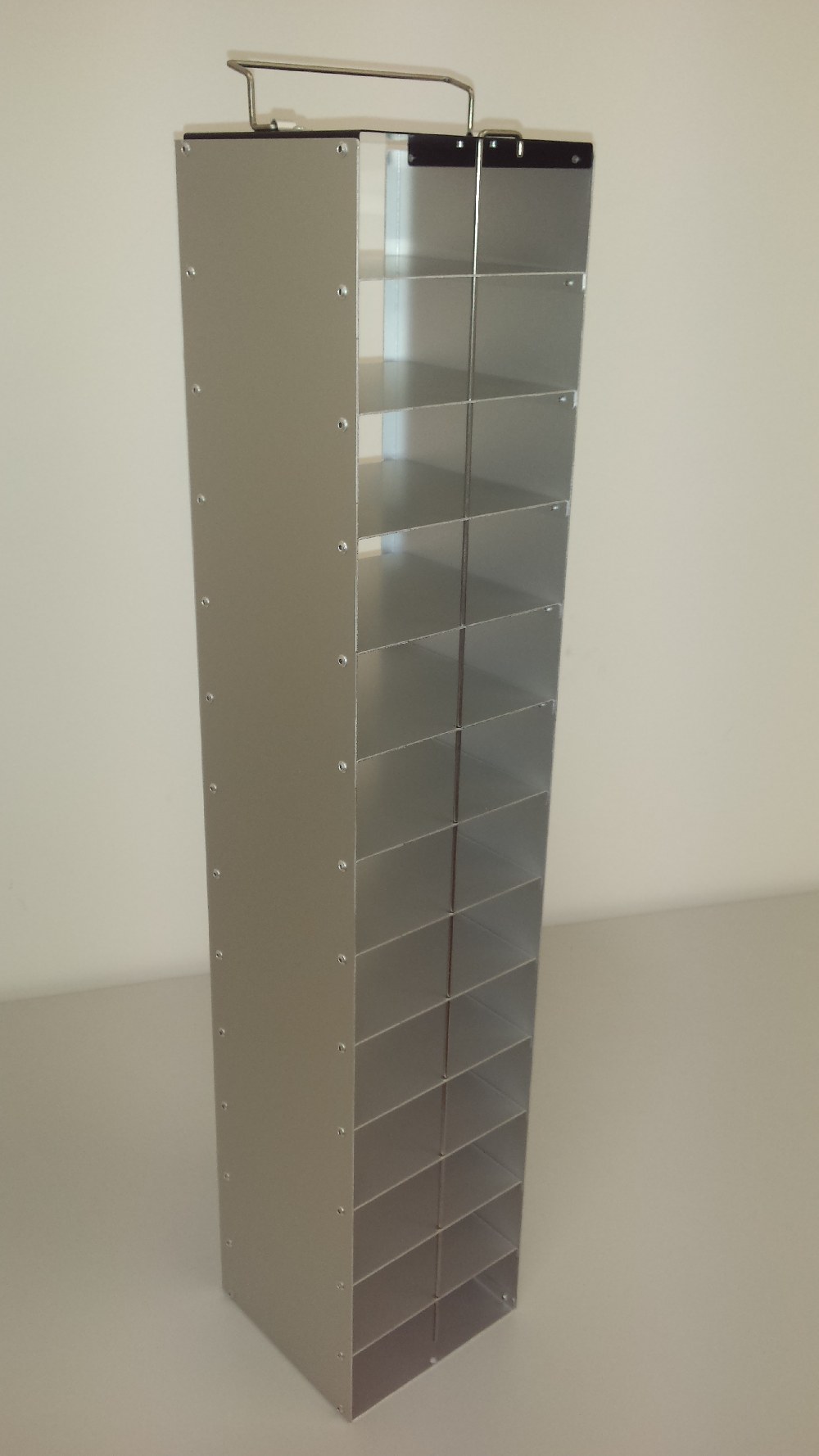

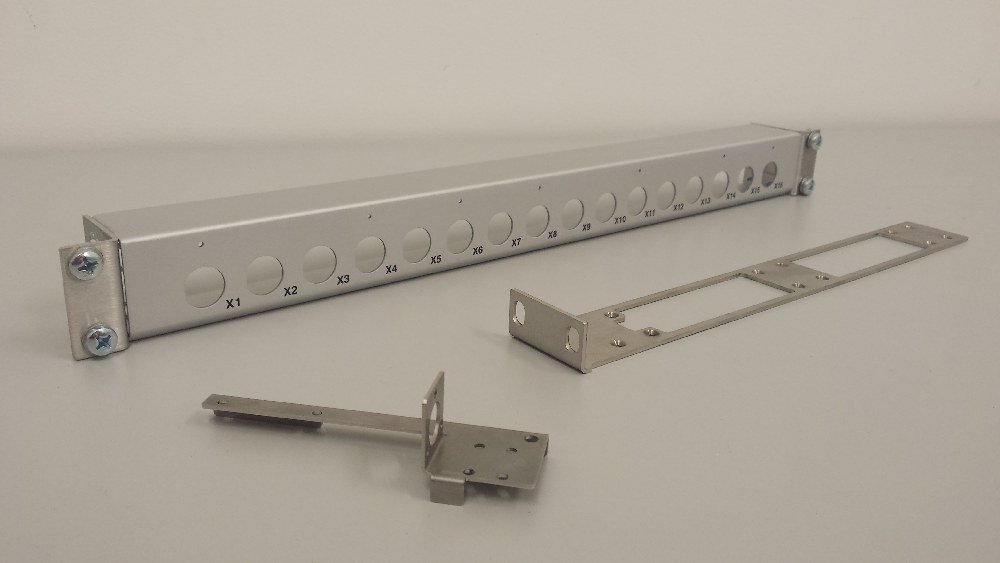

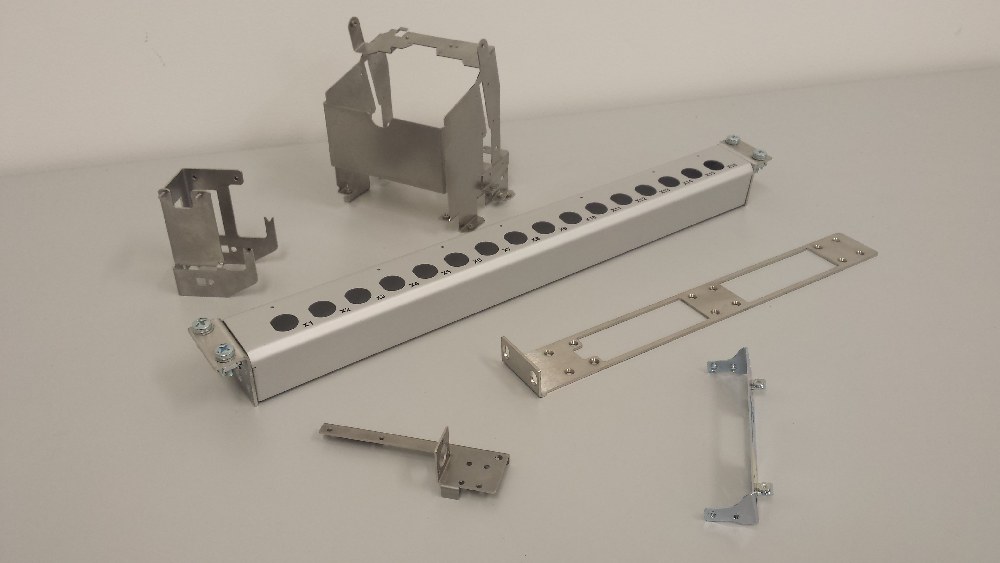

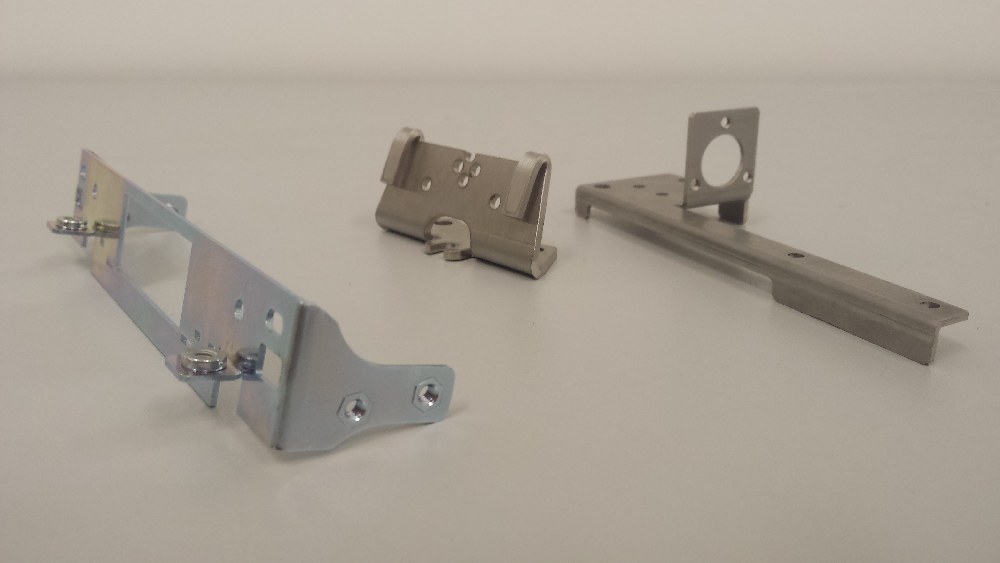

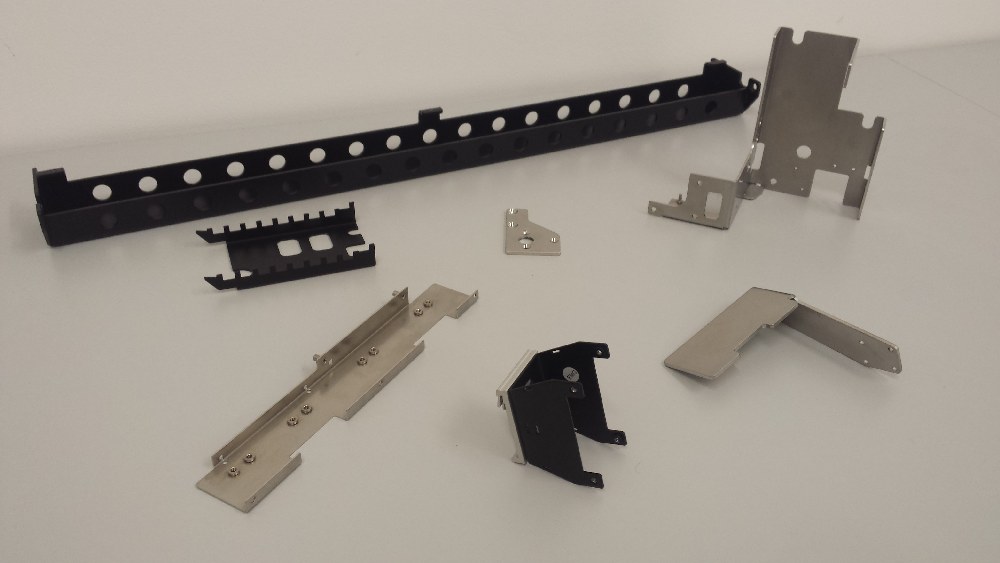

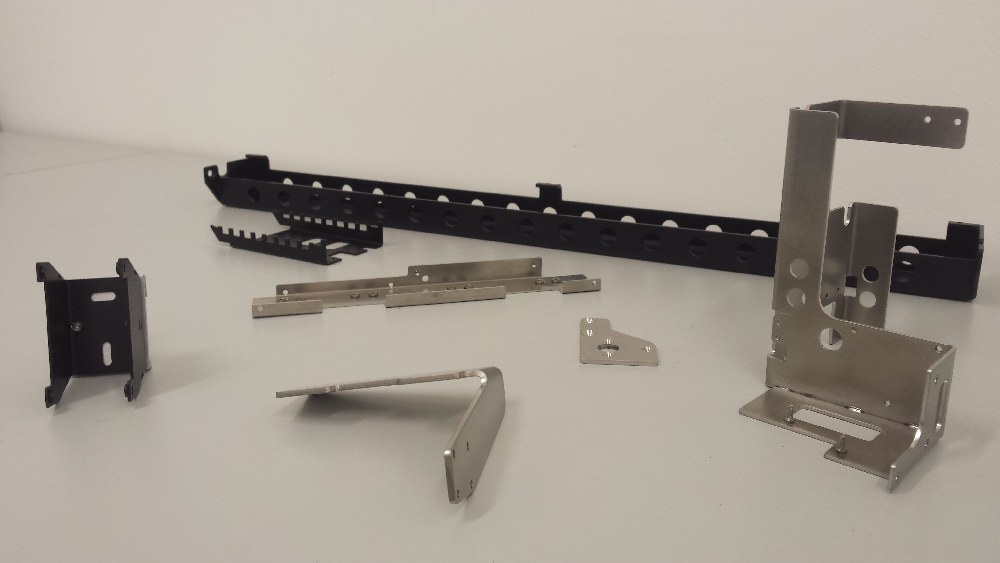

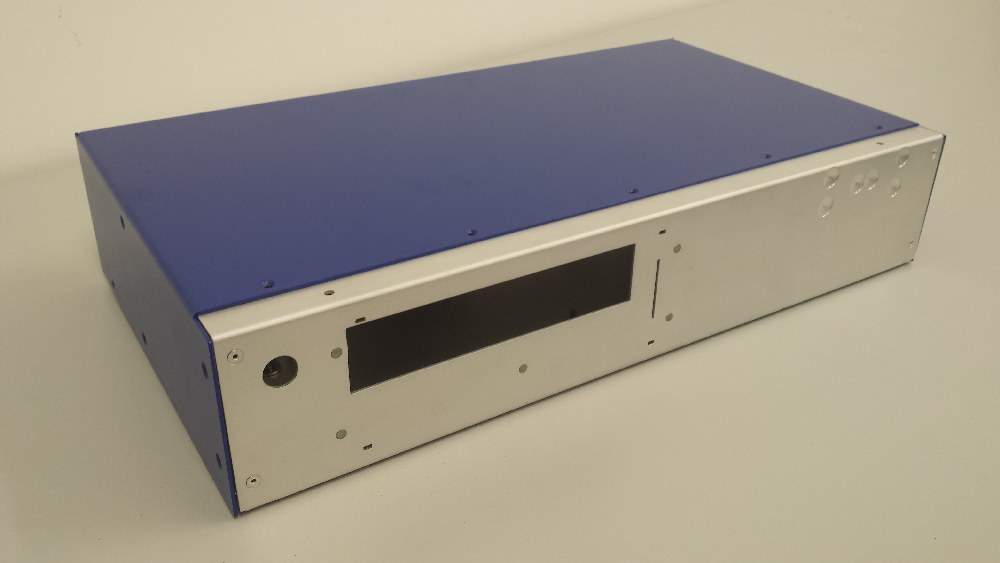

EXAMPLES OF OUR SHEET METAL PRODUCTS

Standard industry format 19" rack units and modules and switching cabinets of all shapes and sizes. Design and production of laser-cut and press-braked custom instrument boxes and cabinets and electronic housings in small- to medium sized lots.

ASSEMBLY OF OUR SHEET METAL PRODUCTS INTO FINISHED PRODUCTS

THE DEVELOPMENT OF OUR COMPANY IN A FEW IMAGES

On account of our development and increasing number of tasks, in 2014 we purchased an adjacent building. Following its complete refurbishment and conversion according to our needs, our production area increased by approx. 1000 m2. Here, we installed primarily laser cutting and punching machines, which serve our partners.

In 2015 this process continued with the refurbishment of another hall and creation of a more modern working environment.

In 2016 we took the next step towards development and the elimination of external work processes when we created our powder coating hall. This now allows us to carry out the powder coating of parts and units manufactured by us in excellent quality.

EMG-Metall sheetmetal technology

EMG-Metall sheetmetal technology