Technology

Decades of experience and 21st-century sheet metal working by our highly trained colleagues. We offer sheet metal working and parts fabrication in small- to medium-sized lots using CNC laser cutting machines, machining centres, and press brakes. Our metal working projects are backed up by our decades of experience and modern machine park.

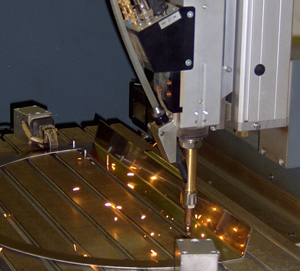

Our TruLaser 3030 laser cutting machine combines innovative technologies with high laser power to ensure better productivity for you.

Various cutting heads for a given sheet thickness and pallet changer for rapid sheet exchange.

Operating range:

1.500 x 3.000 mm -

steel 15mm,

alu 8mm, stainless steel 12mm

Our TruLaser 3030 fiber laser cutting machine is the basis for flexible and economical production.

It profitably cuts all sheet thicknesses, from non-ferrous to thin sheets, with the highest quality edges.

Operating range:

1.500 x 3.000 mm - steel 20mm, alu 15mm, stainless 15mm, copper 6mm, bras 6mm, coated steel sheet (galvanised and hot-dip galvanised)

Our TRUMPF Trumatic 5000R sheet metal working centre reduces the production and material unit costs of products through its efficient use of sheet metal. This high-speed sheet metal machining centre can perform every possible punching and shaping task without scratches.

Operating range:

1.250 x 2.500 mm

Up to 6 mm material thickness

CNC press brake

Hämmerle 3P 80 CNC press brake for precise sheet metal bending operations.

Bending length: 2100 mm, 80 tonnes

CNC press brake

Amada HFP 50-20 CNC press brakes for sheet metal bending requiring dexterity.

Bending length: 2000 mm, 50 tonnes

AMADA EG-4010 press brake, with electric drives.

Bending length: 1050 mm, 44 tonnes

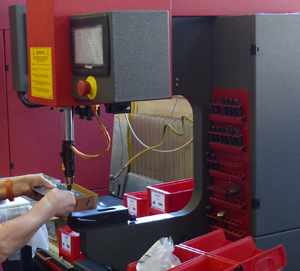

Our Haeger OT824 automated fastener insertion machine can perform tasks with 72 kN insertion force and up to 610 mm frame depth. Nuts, internal and external thread studs, and spacers from size M3 to M6.

Our Haeger 618 fastener insertion machine can apply an insertion force of 54 kN, up to 458 mm frame depth. Insertion of nuts, internal and external thread studs, and spacers.

TimeSavers deburring machine

Table size: 1.250 x 1.250 mm

Grindingmaster manual deburring machine

Table size: 400 x 800 mm

Qualiweld / HBS dual-head stud welding robot with automatic feeder.

Work table size: 1500x1250

Working dimension range: 1250x1050

Applicable fasteners: threaded and threadless studs, spacers.

Materials: copper-clad steel, stainless steel, aluminium

Work table size: 700x370

Working dimension range: 500x300

Applicable fasteners: threaded and threadless studs, spacers.

Lorch welding machines (MIG, MAG,WIG)

Messer spot welding machines

Materials: copper-clad steel, stainless steel, aluminium

Lorch welding machines

(MIG, MAG, WIG)

Messer spot welding machines

HBS manual and CNC stud welding machines

NEW! Pre-treatment with modern duplex technology, using powder paint from a Swiss supplier, with curing in a convection oven.

Workpiece dimensions:

2.500 mm x 800 mm x 1.500 mm

Weight: 120 kg

HAAS ST-15 CNC turning center

With 305 mm x 406 mm max capacity and 64 mm bar capacity

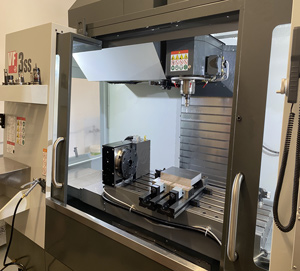

HAAS VF-3SS Super-Speed CNC Vertical Mill with 1016 x 508 x 635 mm travels

HAAS UMC750 5-axis simultaneous machining center Mill with 762 x 508 x 508mm travels

Micro 3D Coordinate Measuring Machine + RENISHAW PH20

Measuring Range: X: 600 mm / Y: 1000 mm / Z: 500 mm

Measurement accuracy: MPEE=2,3 + L/350 μm

Press brakes, compactors, drilling machines, guillotine shears

Kaltenbach sawing machine

EMG-Metall sheetmetal technology

EMG-Metall sheetmetal technology